Applications

Thermaflame 3000 may use in blast furnace instrumentation, curing systems, glass fabrication, plastics manufacturing, industrial overhead cranes, offshore oil rigs, flue gas monitoring, e-beam and x-ray sterilization and other applications where a cable is required to perform in temperatures from -320°F through 1000°F continuous or short term exposure to 2800°F.

Features and Benefits

- UL listed 450°C

- Cut, strip, and terminate with conventional tools

- Surface printed with AWG/MM²

- Flexible and easy to work with

- Fire Detector Wire

- Compliant with NFPA 70 (NEC) and Section 800 of the National Electrical Code 2008 Edition

- Maintain integrity to 2000 °F for 5 minutes @125 VRMS<

- Superior electrical properties and high service range

- Color retention when tested 100 days at 350 °C

- Less than 80% PTFE loss @ >25 years, 350 °C

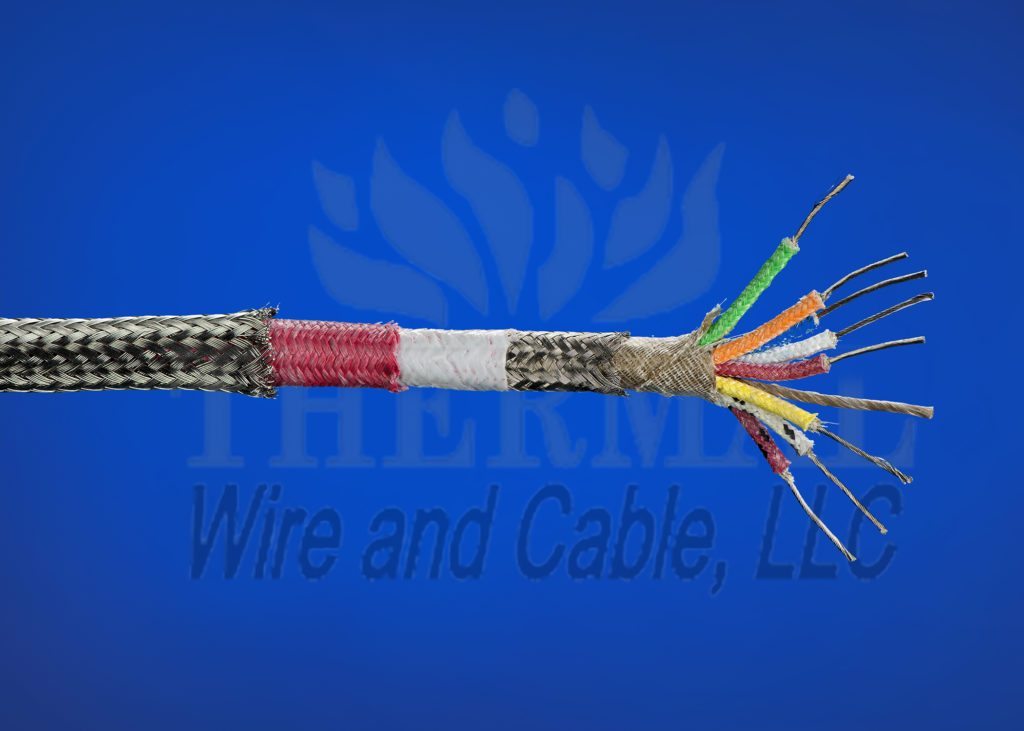

- Wrapped braided and fused PTFE composite tape, layered for high temperature operation and provide moisture impervious and solvent resistant barrier up to 350 °C>

- Passes IEC 60332-1, -2 and -3 (Flame Propagation)

- Passes FT-4 (IEEE 383-1974) Vertical Flame Test

Options

- Available in shielded pairs, triads or with an overall shield, or with thermocouple alloys. Single conductor Thermaflame 3000 also available to 1000 MCM

- Braided Stainless Steel type 304 jacket

- CLX Armor

- 300 Volt version

- Available in 28AWG to 500MCM, to 50 Conductor, or as a composite cable, with various other elements