Applications

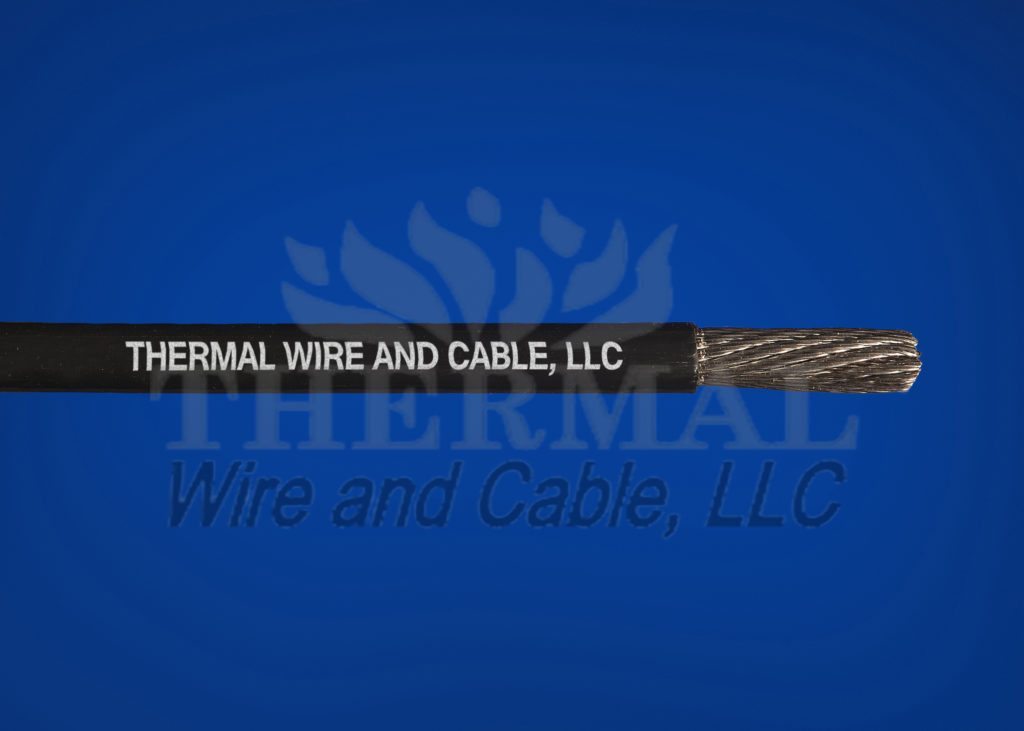

Thermal Wire and Cable Type ZW Cable high-performance wire utilize ethylene tetra Fluoroethylene (ETFE) insulation and are for use per the National Electrical Code (NEC) as conductors for general wiring and in wet environments. Its small diameter profile provides for easy, economic installations. Fully pigmented insulation in bright colors aids in identification. The use of these cables reduces fire hazards in plants, such as petroleum refineries, chemical plants, and steel mill plants, paper mills, processing plants, submersible pumps and nuclear and fossil fuel generating plants.

Compared with other high-temperature cables that are augmented with a braid, ZW wire will slide rather than tear, yet its abrasion resistance helps eliminate cut-through and other damage that can occur during installation and use.

Features and Benefits

- UL Wet Rated

- Abrasion resistant

- 100% glass-free and are OSHA acceptable

- High-stress crack-resistance and also a high flex life.

- Fluoropolymer insulation provides for long term, trouble free performance in the most severe conditions

- Meets National Electrical Code (NEC) latest edition

- Meets UL Subject 13 / UL Subject 83 / UL Subject 94

- NEMA HP-100/HP-100-2 WC-5 (ICEA S-61-402) WC-3 (ICEA S-19-81)

- Passes Verticle IEEE 383 at 210,000/61.5 KW BTU/HR (PVC, PVC-Nylon, XLPE Fail)

- Smaller connectors Smaller conduit

- Chemical resistant insulation

Options

- Insulation Thickness

- 14 – 10 AWG = 0.20 mm

- 8 – 2 AWG = 0.30 mm

- 1 – 4/0 AWG = 0.45 mm

Notes:

Pleae specify color> Last digit in Thermal Wire part #: Change “Color” -1 tan, -0 black, -2 red, -3 orange, -4 yellow, -5 green, -6 blue, -7 purple, -8 gray, -9 white. Stripe color example -100 tan base color with two black stripes.

Ampacity based on single conductor in free air at an ambient air temperature of 40°C (104°F)