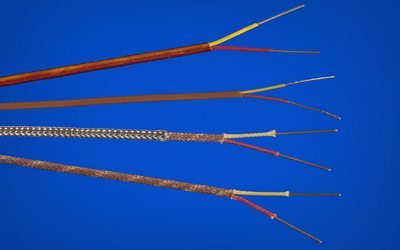

While there are many ingenious strategies – both green and otherwise – that companies nowadays employ to help lower the heat levels in their factories, there still needs to be a device that alerts a company that its internal thermal levels are beyond the point of being comfortable, profitable, or even operable. Most often, the device a company uses is an RTD wire, a worldwide standard for helping monitor factory temperature. And as is sometimes the unfortunate case, these thermocouple wires can fail to function properly for any number of reasons, thereby causing a slow-down, or even a halt, to the production process.

Such was the case with a modern steel company we did business with in Lancaster, PA. A steel mill can run incredibly high temperatures, and this company was no exception. The thermocouple wire they were using was malfunctioning on account of moisture and oil issues and extreme heat and flame, and as a result, they didn’t know whether their factory was running the right temperatures when it came to both productivity and worker safety.That was when Thermal Wire and Cable was consulted. We supplied the steel company with a PTFE augmented cable that solved all their problems. Not only does the PTFE exhibit excellent temperature resistance, being operable in environments of up to 460 degrees Celsius, but its Teflon® composite insulated exterior survives where other cables fail. It’s a high-end, space-age cable that just happens to work well with steel mill applications.

Review our currently available selection of Thermocouple Wires